Joining by High Velocity Forming

The joining of structures is an important application of impulse forming processes. Force-closed, form-closed, and material-closed connections can be obtained. Often, combinations of these mechanisms are used (e.g. form-closed and force-closed).

The advantages of joining by impulse forming processes are the same as those of impulse forming processes in general. E.g., the contactless force transmission allows for joining coated joining partners and the high velocity of the process may lead to a higher formability and decreased springback. Further benefits arise from the fact that no external heat is brought into the joining zone. Thus, in impulse welding, heat-affected zones and other thermal defects are minimized and the process is suitable for the fabrication of multi-material joints, which are not easily obtained by conventional thermal joining techniques. A drawback is that only overlap joints can be produced.

1. Force-closed joining

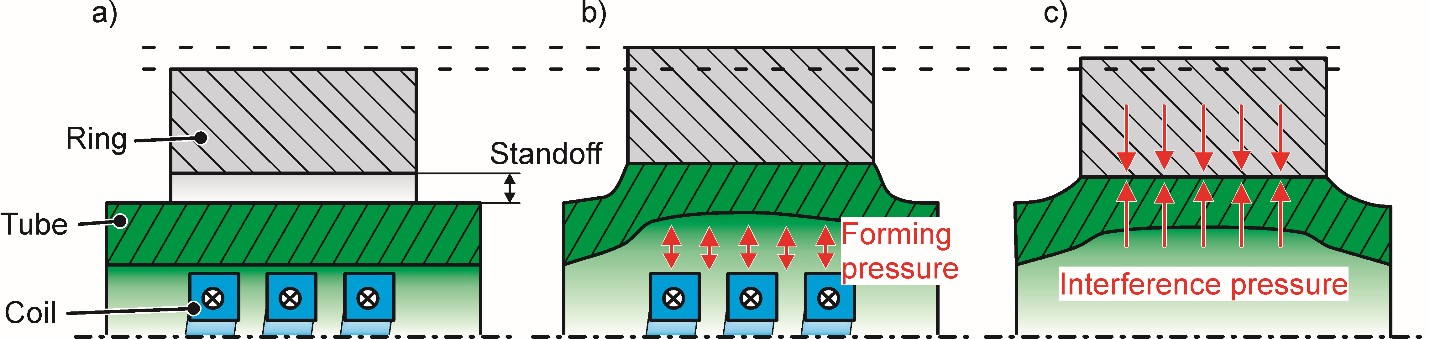

Force-closed joining (i.e. interference-fit joining) is based on the inhibition of a relative movement between the joining partners by friction forces. It can only be applied for profiles or tubes, but both expansion or compression processes can be used. Fig. 1 shows the principle of force-closed joining by expansion. The two joining partners, which need to have different elasto-plastic characteristics, are positioned coaxially with a small standoff (Fig. 1a). Then the inner joining partner expands, e.g., due to the magnetic pressure resulting from the discharge through an expansion coil. The expansion is first elastic, and, if the pressure exceeds the yield stress, plastic. After overcoming the initial standoff, the expansion of the tube leads to a simultaneous expansion of the other joining partner (the ring) (Fig. 1b). This expansion should be only elastic. When the pressure is released, the parts recover elastically. The elastic recovery of the ring must be larger than that of the tube. In this case, the tube prevents a complete recovery of the ring, and an interference pressure is formed (Fig. 1c). The strength of force-closed connections depends on the interference pressure, the contact area, and the friction characteristics, which can be modified by cleaning or roughening of the surfaces.

Figure 1: Force-closed joining by expansion. a) initial setup, b) expansion under magnetic forming pressure, c) interference pressure after elastic recovery

2. Form-closed joining

Form-closed joints base upon the geometrical inhibition of the relative movement. Macroscopic shape elements are included into at least one of the joining partners. The other partner is formed into this shape element. This forming operation is preferably done by impulse forming.

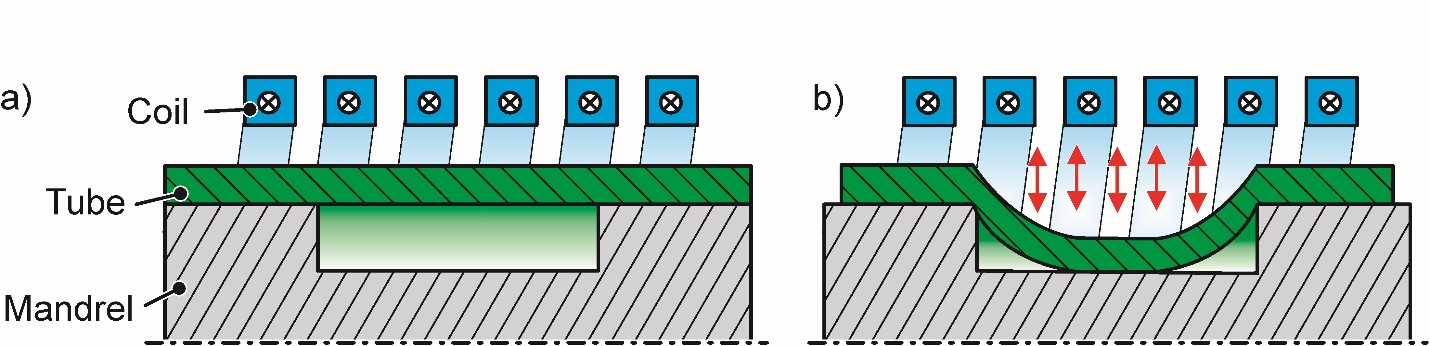

The shape elements are divided into three groups depending on the transferable load. Circumferential grooves or threads can transfer axial loads. Axial grooves or knurls can transmit torsional loads. For the transfer of combined axial and torsional load, discontinuous grooves, pockets, or cross-knurls can be used. The number, geometry, and dimension of the shape elements is decisive for the joint strength. Fig. 2 shows an example of form-fit joining by electromagnetic compression with a rectangular groove. Of course also here, depending on the joining task, expansion processes can be used.

Figure 2: Form-closed joining by electromagnetic compression. a) initial setup, b) after tube compression

3. Material-closed joining

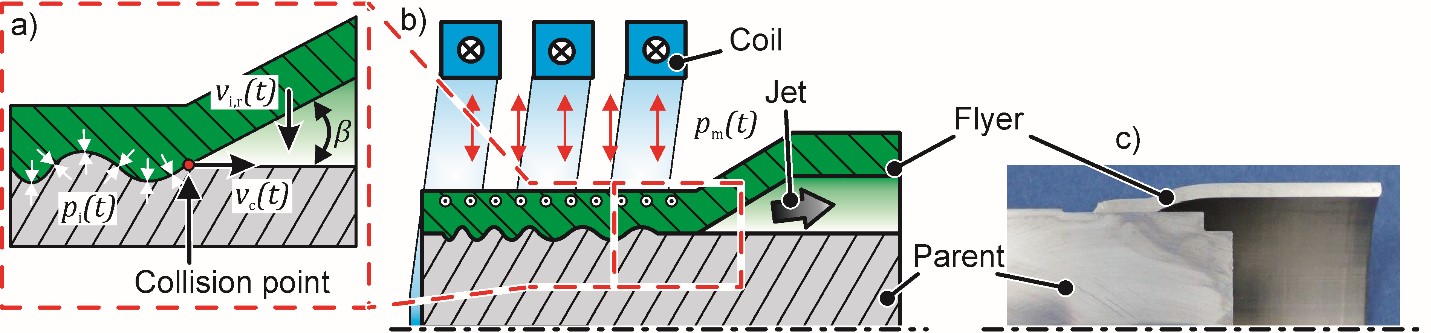

Welding by impulse forming is often used if a fluid-tight connection or a connection with a good electrical conductivity is required. Material-closed joining is based on attraction forces between the two joining partners on atomic scale. In order to activate these forces, the two materials have to be brought in intimate contact. Hindering surface layers like contaminants or oxides must be removed. This is obtained by a material flow called “jet”, which is a result of the intense plastic deformation at the collision point. The jetting effect is provoked by a high velocity oblique impact of one joining partner on the other, see Fig. 3. The normal and axial velocities, the collision angle and the impact pressure are regarded as governing process parameters. The acceleration of the moving partner (the “flyer”) can be obtained in many different ways: by Lorentz forces (magnetic pulse welding, see Fig. 3); through the detonation of an explosive (explosion welding); by shockwaves in water (electrohydraulic welding); by shockwaves resulting from the vaporization of a conductor (vaporizing foil actuator welding); based on plasma from the vaporization of the ablated layer by incident light (laser impact welding), and so on.

Impact welding is regarded as a solid-state process, that is why thermally-induced defects like cracks or intense intermetallic compounds can largely be avoided. This makes the processes especially attractive for welding of materials with different thermo-physical properties. The welding interface usually displays a characteristic wavy appearance.

Figure 3: Material-closed joining by electromagnetic compression. a) Governing parameters at the collision point, b) geometrical setup, c) joined parts